New to epoxy? Before you can master this art, we need to cover one crucial aspect of any epoxy resin project—the drying/curing process.

How Long Does Epoxy Take to Dry?

It depends 😜. The dry time of an epoxy resin pour will rely on several factors.

So first things first, let's get prepared.

- Review the product mixing instructions. With several types of epoxy resin on the market, we can't simply treat them all the same.

- Different formulas act differently in various working environments.

- All of our product mixing instructions are here: https://help.theepoxyresinstore.com/category/59-data-sheets

A correctly measured batch of epoxy resin is essential. Our epoxy resin project calculator is here: https://www.theepoxyresinstore.com/pages/epoxy-resin-calculator

When mixing, slowly scrape the edges and bottom of the container for 3-5 minutes without whipping bubbles into the mix.

Start with consistent room and product temperature. Aim to be within the recommended 68-75F. These temperatures must be consistently maintained throughout the mix, pour and cure process.

Be prepared before starting. The curing process can take up to 72 hours and sometimes a week for the entire project to cure completely.

***Special note

Thicker projects and thin coatings will not cure the same.

For those additional details on completing a thick deep pour river table, follow this link here.

Thin coatings may get tacky to touch within the same day. Sometimes 6-12 hours. It can be quicker depending on the type of epoxy and temperature.

For a fast cure epoxy resin look to our Lightning Tumblers Epoxy Resin. It cures within an hour. View the product details here (New Release - Live on 9/7/2022)

In a thicker 1+" pour project, it may take 48/72 hours for tackiness to set in. It may require a week before the project is solid (not pliable) enough to remove from a mold.

Obstructions to Proper Curing

Additives

The epoxy resin could also refuse to properly cure when mixed with a large amount of color additive. Therefore, the ratio of color additive should be less than 5% of the resin mixture.

Humidity

Humidity also alters the curing process. Many of our experienced users who live in high-humidity areas have reported they work at night and occasionally use de-humidifiers to help. We highly recommend starting with a small project to test if you live in a high-humidity area.

Integral Factors of Epoxy Resin Drying Time

Temperature

One of the main factors of cure time is temperature. We recommend that you work with epoxy between 68-75F. Cooler temperatures slow the drying/curing process, while warmer temperatures speed it up.

Large Volume Projects

Be careful not to start too warm with larger volumes of epoxy resin. Larger volumes of epoxy resin mix will create more heat within the mix and potentially be problematic, resulting in cracking or excess cloudiness. For deeper pour projects, we like to start closer to 68F-72F.

Season Changes

If you live in a seasonal area, the same project created in the winter will not be the same as one completed in the summer. This is because you are dealing with several factors that can alter the curing process during that time of year.

We will continue to add to this article as we experiment and find new information.

In summary, it's always best to test new epoxy resin with a small test. Keep notes on the environment, time of year, time of day, temp., humidity, volume mixed, time to tackiness, time to cure, etc. This will help you the next time, especially if you don't use it daily.

Hope this helps.

Contact our customer support via email or phone below for more information on epoxy drying times.

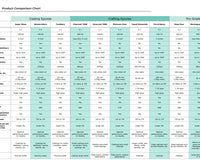

We also created a handy comparison guide to help understand the different properties of our epoxy resin. Just follow this link here https://www.theepoxyresinstore.com/blogs/news/what-epoxy-resin-is-best-for-my-project

https://www.theepoxyresinstore.com/ is an expert manufacturer of various epoxy resins that can be used for your craft projects, professional projections, and industrial applications. We also offer colors, pigments, glitter, and other additives for various epoxy resin projects.

The Epoxy Resin Store

support@theepoxyresinstore.com

Phone: (951) 677-0400

Address: 540 Crane St suite A Lake Elsinore, CA 92530

https://www.theepoxyresinstore.com

Social Accounts:

https://www.facebook.com/TheEpoxyResinStore

https://twitter.com/epoxyresinstore

https://www.linkedin.com/company/the-epoxy-resin-store

https://www.youtube.com/channel/UC3NKcCrYL5uHK-sH5XMQ9HA https://instagram.com/theepoxyresinstore

9 comments

Stonhy

Many questions and comments, but no answers, where are the answers to the questions people ask.?

pat murphy

some of my resin pieces get cloudy, and sometimes i get what they call fish eyes. is this because of temperature?

Larry Booth

The article says, “You can speed up the drying time by working in a room with a lower temperature.” Shouldn’t it read, …in a room with a WARMER temperature?

Smith Kathy

Last winter I had half of my resin filled molds on a heating pad I had covered with a towel last winter and set it on the lowest setting. I left the others on the table. The ones on the towel covered heating pad cured much faster than the ones that were just setting on the table.

Sharan

I heard if a heating pad is incorporated in the curing process it speeds up the process, is that true?

Inquiring minds want to know. Well, really my mind.

Thanks

Robert nicely

I have a swimming pool that the steps into the pool has a about 8inch crack the steps are fiber glass do you have spicy that would work under water

Linda C Smith

I want to seal my pour paintings with resin. Is this the type of resin I should use? If not, what kind would be best?

Carrine Tabor

Thank you for the information. I’m new to expory resin but I love it. But I’m having a few problems, I mix it like it suppose to be, but I’m having problems with holes, and floating. What am I doing wrong?

Day

I am looking to make pens and bottle stoppers the largest is 2”x2” will this resin work and do I need a pressure pot to remove the bubbles