So what is the difference between the epoxy and the resin, or are they the same?

Simply stated, the term epoxy is commonly used to refer to the cured end product of the necessary components within epoxy resin. It is also a colloquial name for epoxide.

This cured end product is the result of when you mix resin with hardener (two-part resins) or expose it to ultraviolet light (UV resin).

Epoxy resins, also known as polyepoxides, are a class of reactive prepolymers and polymers. Of course you can find where to buy resin for your project from our online store or other online sources, but you should know there isn't a "one size fits all" approach.

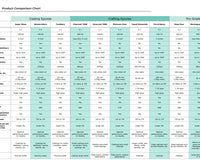

We specialize in manufacturing various epoxy resin types specific to several different types of uses. You can see a comparison chart detailing our various types of epoxy resin we manufacture by following this link here.

What Is A Resin?

In polymer chemistry and material science, the resin has been a solid or high viscous substance of plant or synthetic origin that is typically convertible into polymers. More recently, synthetic resins have been formulated using epichlorohydrin and diphenols, or bisphenol-A with epichlorohydrins.

There are several types of these combinations many with specialized formulas, but these are the most common epoxy resin

- Urethane resin

- Polyester resin

- Casting resin

- Epoxy coating resin

Urethane Resin

- This is a one-component water-based urethane that will protect your project with a nice glossy finish.

- These resins typically have a shorter working time.

- Excellent for coating metals, wood, and concrete.

- VOC-free

- Non-toxic

- virtually odor-free

Polyester Resins

- Cure very hard

- Polyester is less expensive than most epoxy resins

- That is commonly used in the marine industry such as boat building

- Used for the casting of bumpers or gutters and repair of plastic parts.

Casting Resin

- They are typically low viscous compared to epoxy coating resin

- They are made explicitly for casting works such as molds, figurines, filling wood, deep pour, and jewelry.

- Unlike coating resins, casting resins have a thinner consistency and take a longer time to dry. Casting resin takes a longer processing time, and it can take up to one week to cure completely.

- This thinning feature of casting resin allows it to penetrate and fill even the tiniest gaps and cavities.

- Casting resin allows you to cast thicker layers as compared to epoxy resin.

- The thin consistency enables layers of paint to mix quickly.

- Casting resin is specially made for particular applications.

- They can be colored with color pastes, alcohol inks, and color pigments.

Epoxy Resin for coatings

- That is mainly used coating applications

- Epoxy coating resin has a more viscous consistency as compared to casting resin.

- It dries or cures faster than casting resin.

- Compared to casting resin, epoxy coating resin has relatively shorter processing times.

- Because the ink layers do not mix, they can be better controlled.

- Epoxy coating is more resistant to mechanical influence as compared to casting resin.

- Epoxy coating is suitable on rougher surfaces and is water-resistant.

- They can be colored with color pastes, alcohol inks, and color pigments.

Additional Tips for Using Epoxy Resins

When working with epoxy resins, proper preparation and safety are crucial. Always ensure you wear protective clothing, gloves, and a breathing mask, especially in enclosed spaces. Following the manufacturer’s guidelines for mixing ratios is vital for achieving the best results.

High-quality clear casting resin and proper mixing ratios lead to better results for your project. Misunderstanding whether to use casting resin or epoxy coating resin can be problematic. Feel free to reach out to our customer service for specific help, or start by researching our epoxy resin comparison chart by following this link here.

Common Applications of Epoxy Resins

Epoxy resins are incredibly versatile and are used in a wide variety of applications, including:

- Craft projects and DIY home improvements

- Industrial applications such as coatings for floors and surfaces

- Marine applications for boat building and repair

- Jewelry making and small casting projects

- Creating durable, decorative surfaces like countertops and bar tops

We also offer a range of colors, pigments, glitter, and other additives to customize your epoxy resin projects. For more information and to explore our products, visit our online store at The Epoxy Resin Store.

Safety Precautions:

It is important to always to wear protective clothing and a breathing mask when dealing with epoxy resin and especially if you are in a closed room to cast resin.

Using high-quality clear casting resin and proper mixing ratios gives you better results for your project. Not knowing whether to use casting resin or epoxy coating resin can be problematic for your project. Reach out to our customer service for specific help or start researching our epoxy resin comparison chart by following this link here.

We hope this guide was helpful. Let us know what you would like to create in the comments below.

**If you made it this far, we occasionally pick the best comment to win a giveaway. -hint-hint

We created a handy comparison guide to help understand the different properties of our epoxy resin. Just follow this link here.

The Epoxy Resin Store is an expert manufacturer of various epoxy resins for both craft projects and industrial applications. We also offer colors, pigments, glitter, and other additives for various epoxy resin projects. Explore our all-in-one store at The Epoxy Resin Store.

- All in one store - The Epoxy Resin Store

support@theepoxyresinstore.com

Phone: (951) 677-0400

Address: 540 Crane St suite A Lake Elsinore, CA 92530

https://www.theepoxyresinstore.com

Social Accounts:

https://www.facebook.com/TheEpoxyResinStore

https://twitter.com/epoxyresinstore

https://www.linkedin.com/company/the-epoxy-resin-store

https://www.youtube.com/channel/UC3NKcCrYL5uHK-sH5XMQ9HA

https://instagram.com/theepoxyresinstore

#epoxyresin #resinart #epoxy #resin

31 comments

Lee

Thank you for providing the details on the types of resin. I have started making items from casting resin but was looking for the details on coating resin and how it is different. I will not be better informed on the viscosity needs of my next project.

Tammy Morris

Thank you for this amazing article. i love the effect of resin and colors how it reacts to the slilcone drops is what got me hook, line and sinker. The depth is just beautiful. i want to learn more, make more and yeah more. lol Again Thank you.

John Pfeifer

What’s the best resin or epoxy mix to make a crystal ball? Used the basic 1to one ratio stuff and had lots of bubbles and the bottom took a week to harden??

Janastasio

Puedo usar esto en lablas de cortar alimentos? Queda dura o tipo goma? Hay alguna que me funcione para que no se scratch?

Christine

I’m trying to make a swirly glitter floor in our escape room but struggling to understand what epoxy resin to use

Jessica

Great article. I am beginning to fable in this medium and this is great information. So glad a ran across you. I am super excited about the glitters! Everyday is a day to sparkle!!!

Betty

I have a round tray with a 2" rim. I want to coat the bottom and embed little keepsakes (beach glass, sea shells, etc.) It will be used for serving, so, nontoxic is important. Which if your products would be best? Thanks!

Tasha

My project is top secret b/c it’s guaranteed to be a money maker!! 🤑 But, my mold didn’t hold and I have to start again. Your article explaining the different types of product is helpful! Now, I’m going to peruse your site to see what products I can buy.

Susan Hoagland

Hey! No comments on here since last year?

Are ya still here? 😂

Moving in a month, and will JUST be starting my journey into this beautiful world!

I would like to make EVERYTHING, truly.

Could be a problem…Presents welcome.:)

Will

Hello,

I’m looking for the best way to inlay a pink granite “look” on a busy concrete walkway.

The existing broken inlay has little chunks of what looks like crumbled clay brick pieces. I would like to show you photos of the existing inlay and would appreciate suggestions. How may I send the photos?

Marian

Hi, that is a great explanation of resin. How about resin and natural timber. I want to upcycle an old a metal framed tabletop with natural timber slices for use outdoors. What is your advice about this and using resin? It previously had a tiled surface, I don’t want to repeat that look. Marian

Melissa Jedlicka

Thank you for teaching this handy breakdown of resin types and uses! I’ve downloaded your pdf guide!

Ms. My

Nice! Epoxy-coating resin is thicker. It cures or solidifies more quickly than molding resin. Epoxy-coating resin has comparatively faster production periods than casting resin. The ink levels can be better regulated because they don’t combine. https://seattleepoxyflooringwa.com/

Vernon

I understand the mix ratio of an epoxy might be defined as 2:1, but what if my process is slight imprecise? What is the difference in the end product between a ratio of 1.9:1 and 2.1:1?

The love resinator aka Meagan

Thanks for the info.. it’s finally time

To pop the cherry off my resin top after 4 years of looking into it and becoming confident enough to now say… YES! Let’s do it! Let’s finally do it! I’m ready! TONIGHT!!!!

June

I’m new to using resins but I want to make a thin resin based saxophone that I can put into a picture frame. I can’t find a mold and I actually need directions. Can you help me with this?

June

I’m new to using resins but I want to make a thin resin based saxophone that I can put into a picture frame. I can’t find a mold and I actually need directions. Can you help me with this?

Leanne Wheeler

I’m looking for a resin or epoxy that is UV resistant as well as heat resistant. I want to make trivets so it would need to be able to handle 350-425 degrees.

Thanks in advance. I’m new to this and I really appreciated this article.

Aloha

jill

Thank you I am just starting all this with my students!

Danny Williams

I want to use epoxy mixed with pea stone to fill the gaps in a flagstone walkway. Not sure exactly what kind of epoxy would be needed for this kind of application. Any advice?

Daryl

Thanks very much for the explaination. I’ve been woodworking for years but am still a novice when it comes to resins and this was really helpful.

Darwin Bell

I am still fairly new at using epoxy/resin and I am having the hardest time finding coverage information. Most kits that I see in the store will state a square footage that the kit will cover but none of them state the thickness of the pour that that square footage is based on. Even the calculators aren’t clear on the thickness. Where can I find that information.

Jerry M.

I must need better ventilation. I read the entire article and still don’t get it. I better turn up the exhaust fan and read it again.

Seriously though, I’ve been experimenting with a 2 part, 50/50 mix with average results. Your article splains a bunch. Thanks a ton.

Vanessa S

Thank goodness someone took the time to explain in simple terms what the differences were because if I watch another YouTube explanation my head will explade

J Hud

This article was an excellent explanation for those of us just getting started in resin casting. Its so important to respect the materials in any “hobby!” Just because its a hobby, doesnt mean it is risk-free.

Rosemary

I am a total novice. I want to make a miniature bath with “waterl, a nd when hardened, top it with crystal bubbles, for a doll house. Tutorials on line demonstrate this with epoxy resin using equal quantities of resin and hardener. I’ve just seen another tutorial for silk flower arrangement using casting resin and a much smaller quantity of hardener. Which is better for my purposes?

Shawn

I saw a canvas with resin/epoxy poured onto it in a dripped manner that had an abstract appearance over the painted canvas. I would like to try it but I am unsure which product would work. I do have pics to share of the art that I am trying to emulate. BTW, I am not an artist- just wanting to be a bit creative.

Robert v potter

what surface will release the coating after casting

Jesse Corcoran

About time someone explained it like this.. Amazing job explaining the differences. I am also thrilled you covered the importance of protective gear.

-Jesse

Jesse jackson

Thank you, the article was very informative.

Charlotte

Could you please explain to me why after a project has been poured and set up say a 3 tier cake mold why after putting it together it will start bending usually the bottom tier but sometimes the middle one also, what am I doing wrong? I am using Clear Epoxy Resin.